...a place to stand...

[Prototypes] [Sockets] [Visualizations] [Interlude] [Bottom Support] [Archimedes?] [More] [Pre-Comp] [Countdown] [First Week] [a place to stand] [Black Rock City] [Aftermath]

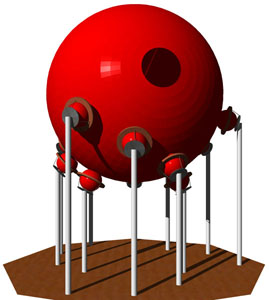

Bowling Ball Bearing Sockets

Details of construction of the bearings I'm using (so far) to allow the ball to rotate.

Click for annotated version

[med] [big]

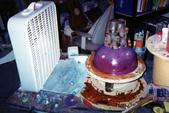

This is the first of the prototypes using a bowling ball. Previous 2 protos were 'pads' the shape of the sphere with embedded rotatable marbles. (I may go back to that for at least part of the suspension system.)

[med] [big]

[med] [big]

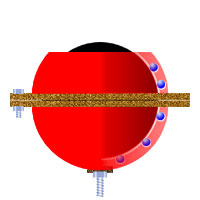

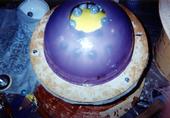

This is a view of the inside of the socket and the marbles on which the bowling ball is supported.

[med] [big]

[med] [big]

Once the first bowling ball proto was done, I started to 'mass produce' the sockets, starting with cutting 16' diameter rings.

[med] [big]

I made a cradle to more securely hold the ball than the piles of metal blocks I used above.

[med] [big]

A ring is attached to the cradle with several layers of well vaselined wax paper between. This will allow the 2 halves of the socket to come apart later. The center part is cut away at slightly less than the diameter of the ball.

[med] [big]

A thin layer of clay is spread over the surface of the ball. This will give a bit of space between the fiberglass and the ball.

[med] [big]

In a seperate operation, I've prepared a bunch of 1" marbles by coating each with wax. When the balls are soon covered with fiberglass, the wax acts as a temporary spacer so that each marble will be able to spin in it's own socket-once the wax is removed.

[med] [big]

Depresions in the clay await wax-covered marbles.

[med] [big]

36 waxy marbles ready for fiberglass.

[med] [big]

This bowl will act as the form for the top half of the socket.

[med] [big]

A LOT of heat can be generated when the fiberglass sets-especially when there is as much of it as in the finished socket. To prevent the wax from being melted off the marbles, each is coated with a very thick mixture of resin and carbosil or other powdery additive to make it stick to the marbles. The red comes from dye added to the resin.

[med] [big]

When all covered with formerly gooey but now hardened resin, the top form is covered thickly with vaseline and placed on top.

[med] [big]

More resin is added, this time with a bunch of chopped glass fibers. The glass adds a lot of strength and reduces the cost of resin.

[med] [big]

When I added just a bit too much catalyst, I'd have to cover the mold with wet towels and get the fans going. I got better at guessing the right amount over time.

[med] [big]

The final product. This was the first one I made (3 so far), and the black regions are ones that got so hot that they burned the red color away.